AI:REPLENISH

Profitable readjustment of goods with AI-supported demand forecasting

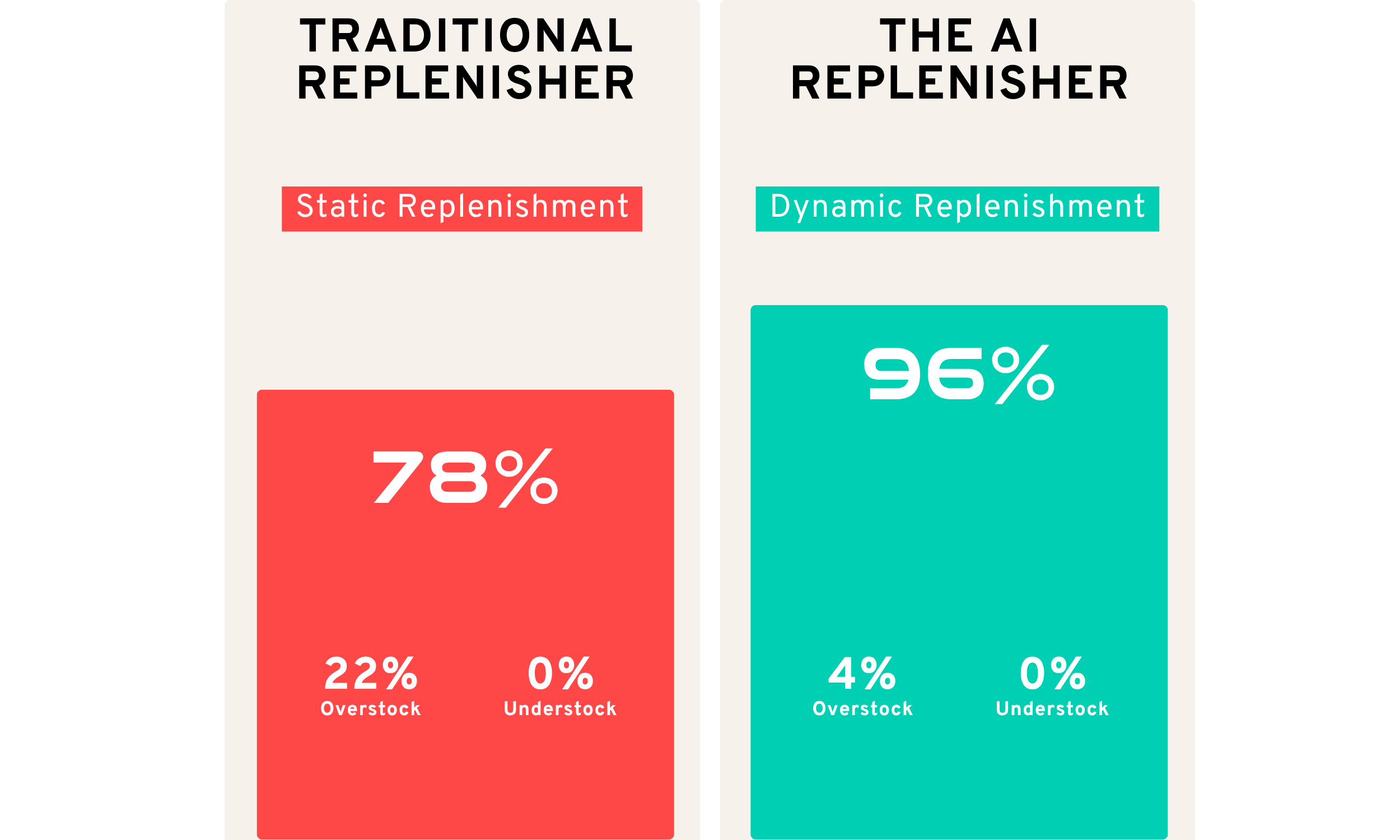

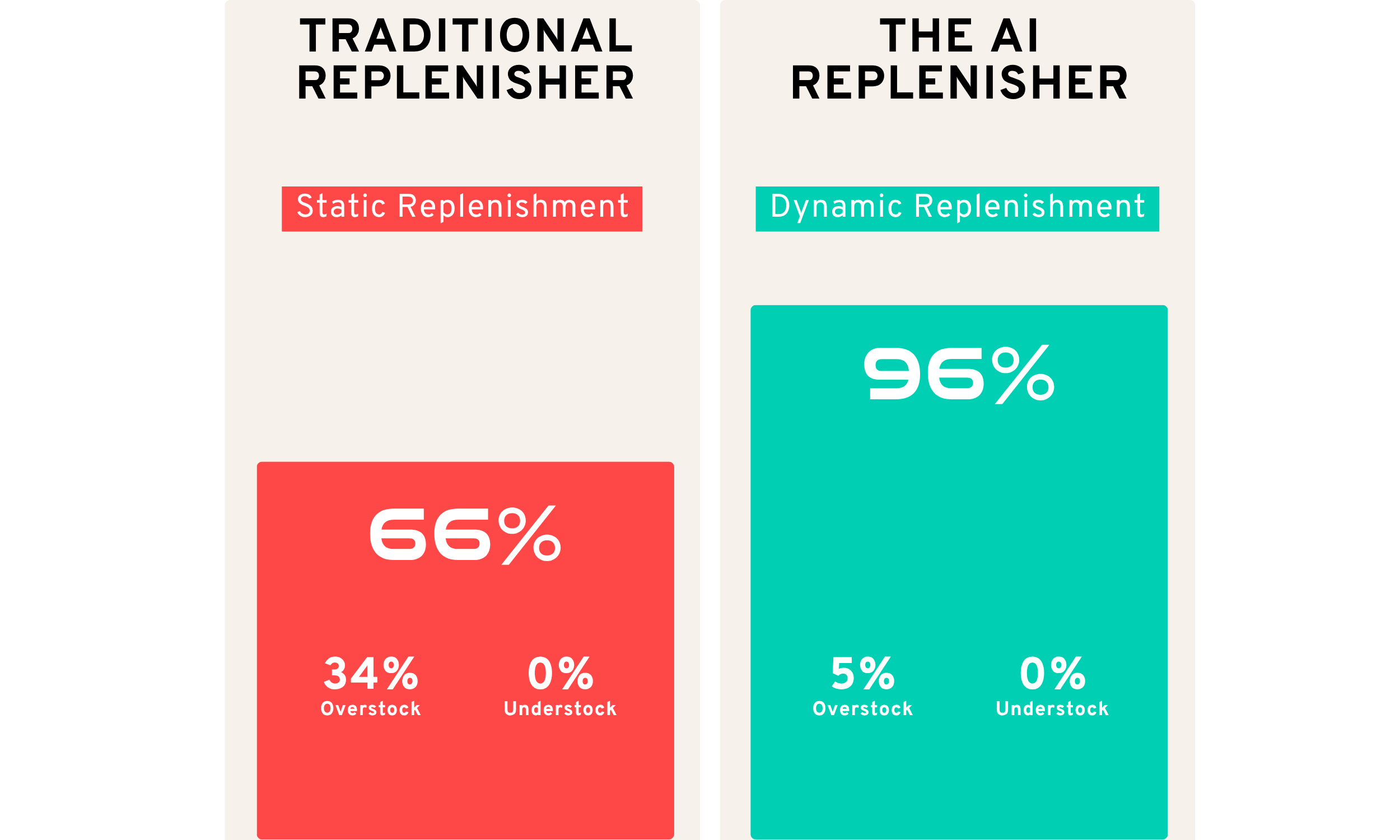

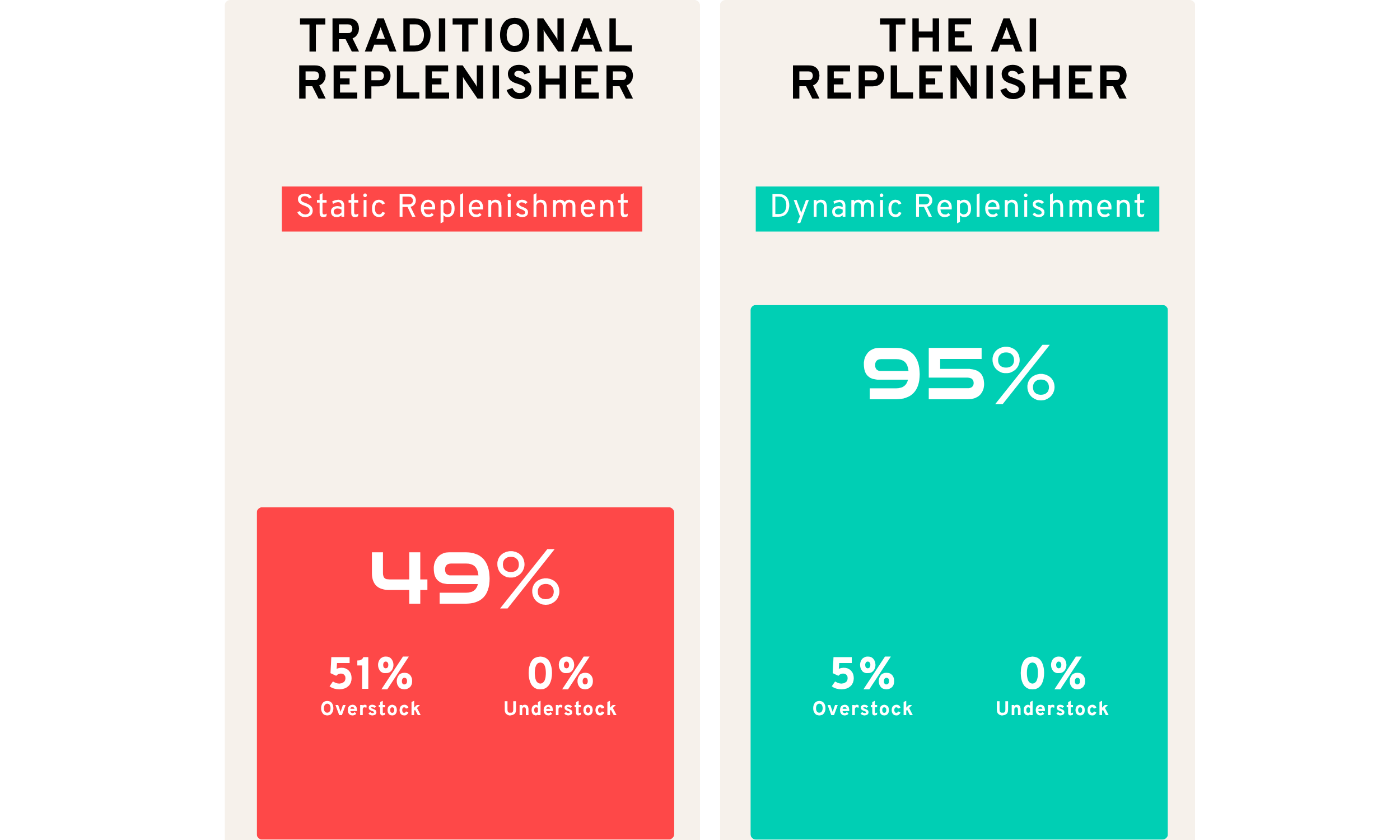

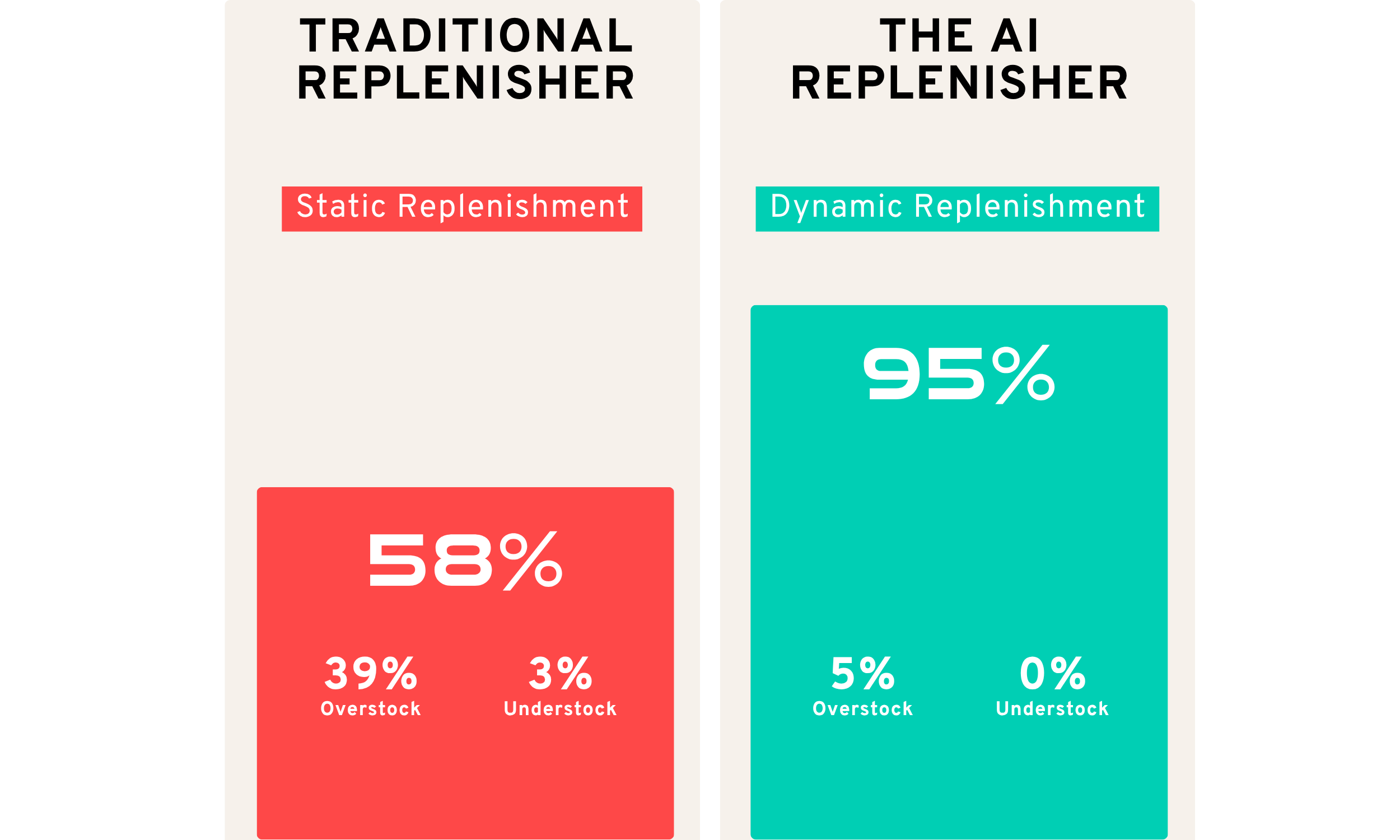

AI:REPLENISH is the answer to dynamic inventory management. Instead of a rigid warehouse logic, the system predicts which item quantities are actually required at SKU and store level, up to 14 days in advance – with an accuracy of up to 96%. Over 100 internal and external factors are taken into account: sales figures, location data, weather, marketing activities, and much more.

The automatic daily stock adjustments are made directly in your ERP system – with no need to change systems and without manual intervention. AI:REPLENISH’s shared industry model ensures maximum forecasting quality: the more retailers participate, the better the system becomes for everyone. Even with limited stock, AI:REPLENISH automatically prioritises the stores with the highest demand. And you still retain control: manage exceptions, rules or entire collections directly in the ERP system or in the customer portal.

Switch from static to dynamic. Benefit from the world’s leading forecasting model.

In use worldwide

With leading brands

Shoeby increases sales by 2.96% with AI Replenish

With the help of AI Replenish, Shoeby creates sales forecasts at SKU level for the brand's 240 brick-and-mortar stores. The min/max stock levels are automatically adjusted in the ERP system - based on current trends in customer behaviour trends and sales performance.

OFM increases forecast accuracy by 29

With AI Replenish, OFM is revolutionizing inventory management - through precise sales forecasts and strategically optimized goods distribution.

Daka reduces excess stock by 47 percent

Daka uses AI Replenish to create sales forecasts at SKU level for the 18 brick-and-mortar stores and to implement individual replenishment strategies. The ERP system automatically adjusts the min/max stock levels based on trends in customer behavior and sales performance.

Van Dal Mannenmode reduces understock by over 90

With the help of AI Replenish, Van Dal has made the switch from a push to a pull strategy. As a result, stock levels can now be managed precisely based on actual customer demand, supported by highly accurate sales forecasts and seamless ERP integration. The result is a strategic distribution of goods, higher sell-through rates, fewer price reductions, increased inventory turnover and significantly less waste.

Utilise the full potential of your stock

With AI-powered replenishment, you can increase sales, reduce overstock, and retain 100% control – directly in your ERP.

Each SKU is calculated individually for each store based on your sales data, seasonality, weather, holidays, campaigns and other parameters. Forecasting is rolling, with up to 14 days’ lead time.

Based on the forecasts, the system adjusts the min/max values in your ERP system on a daily basis - without any system changes or interface issues. Control happens directly within your existing system landscape.

When stock is limited, the system automatically prioritises stores with the highest sales, based on current performance data. Inventory is allocated centrally and efficiently – instead of being scattered manually.

The system uses more than 100 internal and external influencing factors. All parameters - from stock levels to the weather forecast - are incorporated into the forecast. This creates a learning, continuously optimising logic.

Efficiency in every store

What AI:REPLENISH solves for you

Often, it’s the same factors that impact retail profitability and efficiency – even as demand grows. AI:REPLENISH addresses these core issues and brings precision, automation, and flexibility back into your inventory management.

Minimise stock transfers

Less effort, more contribution margin

When items aren’t where they’re needed, costs and complexity increase – for example, through costly store-to-store transfers. AI:REPLENISH identifies such bottlenecks early and proactively manages stock, so transfers become unnecessary.

Make available stock work for you

Smart scarcity management

Out-of-stocks despite demand lead to lost sales – even when products are technically available in the system. AI:REPLENISH solves this with intelligent allocation: items are made available precisely where they are likely to sell, maximising selling space rather than leaving shelves empty.

For many industries

As diverse as your product ranges

AI:REPLENISH adapts precisely to the requirements of your industry – accurate, adaptive and designed for growth.

Whether fashion, sports, lifestyle, beauty or home & living – every industry has its own rules, seasonality patterns and assortment logic. AI:REPLENISH takes these industry-specific dynamics into account. The AI identifies patterns in your stock rotation, adjusts forecasts individually at store and SKU level and ensures intelligent inventory control – whether for fast-moving trends or enduring bestsellers.

The system continuously learns, optimises itself, and remains flexible as your business evolves – so your inventory not only fits, but performs.

Using resources wisely

Scaling without staffing bottlenecks

Your team should focus on strategy – not on juggling spreadsheets. Our AI makes billions of decisions daily at SKU level, stores valuable expertise and delivers reliable forecasts. This allows you to concentrate on what truly drives your business forward.

Want to learn more?Then get in touch with us!

Do you have questions about our products or services?

Send us a message or give us a call.

To process your request quickly, please complete the form.

Your data will, of course, be treated confidentially and used exclusively in connection with your enquiry.

Fields marked with * are required.